| Items |

6063-T6SP40-1000-133

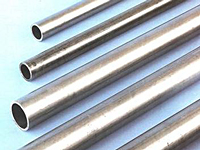

Seamless Aluminum Pipe - Series 6063-T6 Schedule 40

|

6063-T6SP40-1250-140

Seamless Aluminum Pipe - Series 6063-T6 Schedule 40

|

6063-T6SP40-1500-145

Seamless Aluminum Pipe - Series 6063-T6 Schedule 40

|

6063-T6SP40-2000-154

Seamless Aluminum Pipe - Series 6063-T6 Schedule 40

|

6063-T6SP40-2500-203

Seamless Aluminum Pipe - Series 6063-T6 Schedule 40

|

|

Material

|

N/A

Aluminum

|

|

Shapeform

|

N/A

Pipe

|

|

Series

|

N/A

6063-T6

|

|

Grade

|

N/A

6063

|

|

Preparation

|

N/A

Stenciled

|

|

Temper

|

N/A

T6

|

|

Standard

|

N/A

Schedule 40

|

|

Nominal Size

|

N/A

1 inches

|

N/A

1 1/4 inches

|

N/A

1 1/2 inches

|

N/A

2 inches

|

N/A

2 1/2 inches

|

|

Nominal Size

|

N/A

1 inches25.4 mm

|

N/A

1.25 inches31.75 mm

|

N/A

1.5 inches38.1 mm

|

N/A

2 inches50.8 mm

|

N/A

2.5 inches63.5 mm

|

|

O.D.

|

N/A

1.315 inches33.401 mm

|

N/A

1.66 inches42.164 mm

|

N/A

1.9 inches48.26 mm

|

N/A

2.375 inches60.325 mm

|

N/A

2.875 inches73.025 mm

|

|

I.D.

|

N/A

1.049 inches26.6446 mm

|

N/A

1.380 inches35.052 mm

|

N/A

1.610 inches40.894 mm

|

N/A

2.067 inches52.5018 mm

|

N/A

2.469 inches62.7126 mm

|

|

Wall Thickness

|

N/A

0.133 inches3.3782 mm

|

N/A

0.140 inches3.556 mm

|

N/A

0.145 inches3.683 mm

|

N/A

0.154 inches3.9116 mm

|

N/A

0.203 inches5.1562 mm

|

|

Weight

|

N/A

0.5749 lbs/ft0.8555454836 kg/m

|

N/A

0.7782 lbs/ft1.1580892248 kg/m

|

N/A

0.9306 lbs/ft1.3848854184 kg/m

|

N/A

1.2508 lbs/ft1.8613955312 kg/m

|

N/A

1.9835 lbs/ft2.951773294 kg/m

|

|

Weight per 20'

|

N/A

11.497 lbs5.2150392 kg

|

N/A

15.563 lbs7.0593768 kg

|

N/A

18.611 lbs8.4419496 kg

|

N/A

25.015 lbs11.346804 kg

|

N/A

39.670 lbs17.994312 kg

|

|

ASTM Specification

|

N/A

ASME SB-241 ASME SB241M ASTM B241 ASTM B241M Mil-P-25995 UNS A96063

|

|

Length

|

N/A

20 ft

|

|

Ultimate Strength

|

N/A

35 ksi

|

|

Yield Strength

|

N/A

31 ksi

|

|

Elongation percent in 2 inches

|

N/A

12

|

|

Hardness Brinnel Number

|

N/A

73

|

|

Ultimate Shearing Strength

|

N/A

22 ksi

|

|

Fatigue Endurance Limit1

|

N/A

10 ksi

|

|

Modulus of Elasticity2

|

N/A

10.0 x 103 ksi

|

|

Resistance to Corrosion - General3

|

N/A

A

|

|

Stress Corrosion Cracking

|

N/A

A

|

|

Workability (Cold)

|

N/A

C

|

|

Mechinability

|

N/A

C

|

|

Brazeability4

|

N/A

A

|

|

Gas Weldability5

|

N/A

A

|

|

Arc Weldability6

|

N/A

A

|

|

Resistance Spot and Seam Weldability7

|

N/A

A

|

|

Applications

|

N/A

Pipe railing, furniture, architectural extrusions

|

|

Density

|

N/A

0.097 lbs/in³

|

|

Specific Gravity

|

N/A

2.70

|