| Items |

6063-T52T-750-750-125

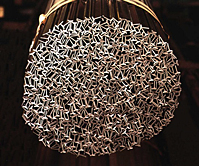

Aluminum Architectural Tees - Series 6063

|

6063-T52T-1000-1000-125

Aluminum Architectural Tees - Series 6063

|

6063-T52T-1250-875-125

Aluminum Architectural Tees - Series 6063

|

6063-T52T-2000-750-125

Aluminum Architectural Tees - Series 6063

|

|

Material

|

N/A

Aluminum

|

|

Shapeform

|

N/A

Architectural Tees

|

|

Series

|

N/A

6063-T52

|

|

Grade

|

N/A

6063

|

|

Temper

|

N/A

T52

|

|

Size

|

N/A

3/4 x 3/4 x 1/8 inches

|

N/A

1 x 1 x 1/8 inches

|

N/A

1 1/4 x 7/8 x 1/8 inches

|

N/A

2 x 3/4 x 1/8 inches

|

|

Working Decimal Equivalent

|

N/A

0.750 x 0.750 x 0.125 inches19.05 x 19.05 x 3.175 mm

|

N/A

1.000 x 1.000 x 0.125 inches25.4 x 25.4 x 3.175 mm

|

N/A

1.250 x 0.875 x 0.125 inches31.75 x 22.225 x 3.175 mm

|

N/A

2.000 x 0.750 x 0.125 inches50.8 x 19.05 x 3.175 mm

|

|

Dimension A

|

N/A

3/4 inches

|

N/A

1 inches

|

N/A

1 1/4 inches

|

N/A

2 inches

|

|

Dimension B

|

N/A

3/4 inches

|

N/A

1 inches

|

N/A

7/8 inches

|

N/A

3/4 inches

|

|

Thickness

|

N/A

1/8 inches

|

|

Estimated Weight

|

N/A

0.1998 lbs/ft0.2973351672 kg/m

|

N/A

0.2716 lbs/ft0.4041853424 kg/m

|

N/A

0.2910 lbs/ft0.433055724 kg/m

|

N/A

0.3822 lbs/ft0.5687762808 kg/m

|

|

Estimated Weight per 25' Bar

|

N/A

3.197 lbs1.448241 kg

|

N/A

4.346 lbs1.968738 kg

|

N/A

4.656 lbs2.109168 kg

|

N/A

6.115 lbs2.76783 kg

|

|

ASTM Specification

|

N/A

AMS-QO-A-200/9

|

|

Stock Length

|

N/A

16 ft

|

|

Ultimate Strength

|

N/A

27 ksi

|

|

Yield Strength

|

N/A

21 ksi

|

|

Elongation percent in 2 inches

|

N/A

12

|

|

Hardness Brinnel Number

|

N/A

60

|

|

Ultimate Shearing Strength

|

N/A

17 ksi

|

|

Fatigue Endurance Limit1

|

N/A

10 ksi

|

|

Modulus of Elasticity2

|

N/A

10.0 x 103 ksi

|

|

Resistance to Corrosion - General3

|

N/A

A

|

|

Stress Corrosion Cracking

|

N/A

A

|

|

Workability (Cold)

|

N/A

B

|

|

Mechinability

|

N/A

C

|

|

Brazeability4

|

N/A

A

|

|

Gas Weldability5

|

N/A

A

|

|

Arc Weldability6

|

N/A

A

|

|

Resistance Spot and Seam Weldability7

|

N/A

A

|

|

Applications

|

N/A

Pipe railing, furniture, architectural extrusions

|

|

Density

|

N/A

0.097 lbs/in³

|

|

Specific Gravity

|

N/A

2.70

|