| Items |

6061-T6RE-250-8000

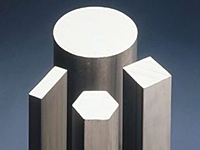

Aluminum Rectangles - Series 6061

|

6061-T6RE-250-10000

Aluminum Rectangles - Series 6061

|

6061-T6RE-250-12000

Aluminum Rectangles - Series 6061

|

6061-T6RE-375-8000

Aluminum Rectangles - Series 6061

|

6061-T6RE-375-10000

Aluminum Rectangles - Series 6061

|

|

Material

|

N/A

Aluminum

|

|

Shapeform

|

N/A

Rectangles

|

|

Series

|

N/A

6061-T6

|

|

Grade

|

N/A

6061

|

|

Temper

|

N/A

T6

|

|

Size

|

N/A

1/4 x 8 inches

|

N/A

1/4 x 10 inches

|

N/A

1/4 x 12 inches

|

N/A

3/8 x 8 inches

|

N/A

3/8 x 10 inches

|

|

Working Decimal Equivalent

|

N/A

0.250 x 8.000 inches6.35 x 203.2 mm

|

N/A

0.250 x 10.00 inches6.35 x 254 mm

|

N/A

0.250 x 12.00 inches6.35 x 304.8 mm

|

N/A

0.375 x 8.000 inches9.525 x 203.2 mm

|

N/A

0.375 x 10.000 inches9.525 x 254 mm

|

|

Width

|

N/A

1/4 inches

|

N/A

1/4 inches

|

N/A

1/4 inches

|

N/A

3/8 inches

|

N/A

3/8 inches

|

|

Length

|

N/A

8 inches

|

N/A

10 inches

|

N/A

12 inches

|

N/A

8 inches

|

N/A

10 inches

|

|

Estimated Weight

|

N/A

2.3520 lbs/ft3.500161728 kg/m

|

N/A

2.940 lbs/ft4.37520216 kg/m

|

N/A

3.5280 lbs/ft5.250242592 kg/m

|

N/A

3.5280 lbs/ft5.250242592 kg/m

|

N/A

4.4100 lbs/ft6.56280324 kg/m

|

|

Estimated Weight per 12' Bar

|

N/A

28.224 lbs12.8021918976 kg

|

N/A

35.280 lbs16.002739872 kg

|

N/A

42.336 lbs19.2032878464 kg

|

N/A

42.336 lbs19.2032878464 kg

|

N/A

52.920 lbs24.004109808 kg

|

|

ASTM Specification

|

N/A

AMS 4173 ASTM B221

|

|

Stock Length

|

N/A

12 ft

|

|

Ultimate Strength

|

N/A

45 ksi

|

|

Yield Strength

|

N/A

40 ksi

|

|

Elongation percent in 2 inches

|

N/A

12

|

|

Hardness Brinnel Number

|

N/A

95

|

|

Ultimate Shearing Strength

|

N/A

30 ksi

|

|

Fatigue Endurance Limit1

|

N/A

14 ksi

|

|

Modulus of Elasticity2

|

N/A

10.0 x 104 ksi

|

|

Resistance to Corrosion - General3

|

N/A

B

|

|

Stress Corrosion Cracking4

|

N/A

A

|

|

Workability (Cold)5

|

N/A

C

|

|

Mechinability

|

N/A

C

|

|

Brazeability6

|

N/A

A

|

|

Gas Weldability7

|

N/A

A

|

|

Arc Weldability8

|

N/A

A

|

|

Resistance Spot and Seam Weldability9

|

N/A

A

|

|

Applications

|

N/A

Heavy-duty structures requiring good corrosion resistance, truck and marine, railroad cars, furniture, pipelines

|

|

Density

|

N/A

0.098 lbs/in³

|

|

Specific Gravity

|

N/A

2.70

|